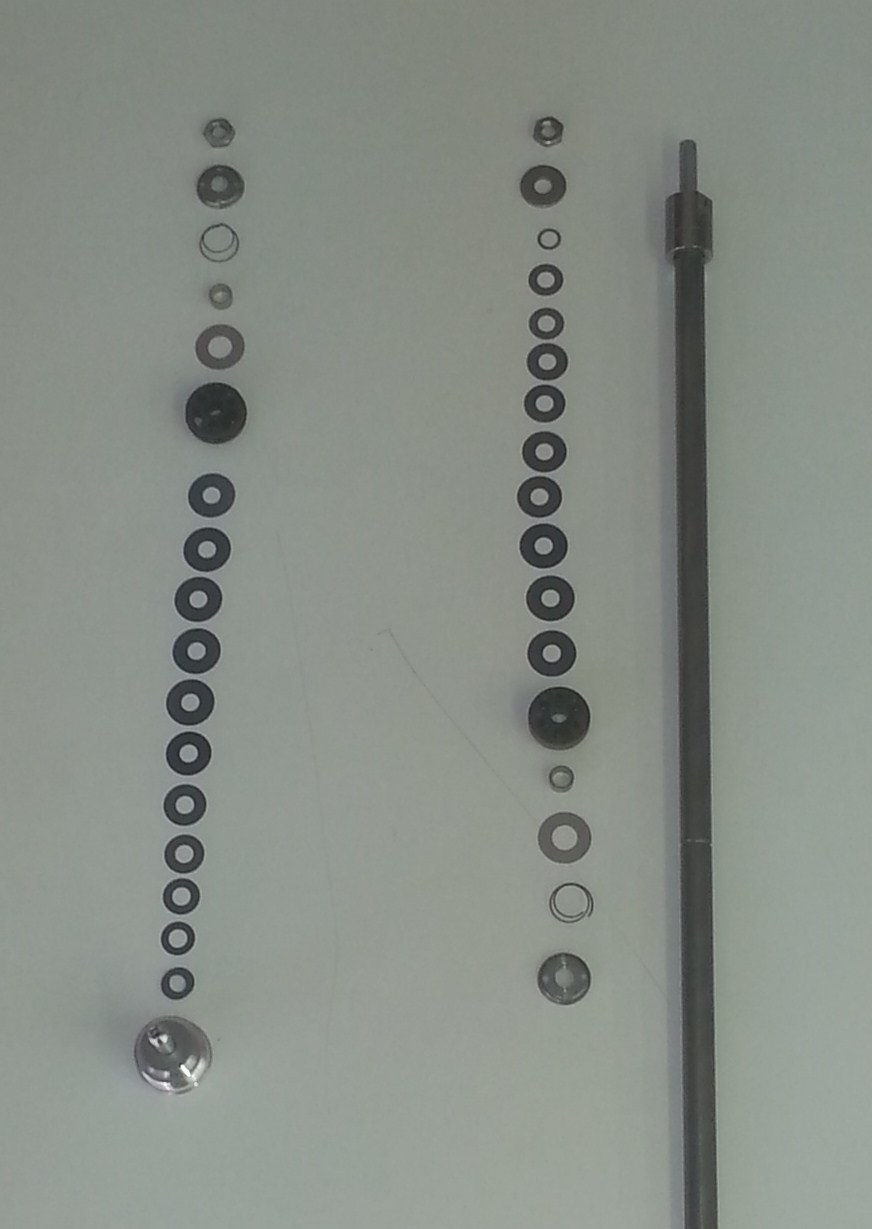

This photo shows a compression piston assembly taken apart on the left with the rebound piston assembly on the right. Starting on the bottom left is the compression holder that threads into the bottom of the cartridge body. Going up we see the compression stack, a bunch of shims stacked up in the shape of a Christmas tree. The piston. The washer, collar, spring and cap make up a one way valve. Nut to hold it all together.

On the right the order is reversed because the rebound piston controls oil flowing the other way. The shim stack is different because compression and rebound damping are opposite jobs.

Far right is the cartridge rod that the rebound assembly is attached to.

How does this work? The shims bend under the force of the moving oil. This opens the passages in the piston. How strong or weak the stack of shims are determines how much they allow the passage to open and therefore how much damping you have. The oil that has to be controlled is only the amount being displaced by the rod moving farther into the cartridge. Or the same amount being pulled back into the cartridge when the rod retracts. The cartridge is always full of oil. Your shock is a shorter version of this.

I change the shim stack to give you the damping you need. $460 to rebuild and re-valve your stock cartridge forks. No expensive kit needed.

Learn more about the pistons here: