Travel O-Rings

Half way done

Small World

My ‘90 TZ 250 was first owned by Stuart H. While Stuart owned it Dale F. and Bruce L. also raced it in AMA 250 GP. I bought it and raced it in Hawaii for a few years then sold it to Jupiter K. who also raced it in Hawaii. Jup sold it to Sean W. who raced it in Hawaii then took it to New Hampshire where it sat in his shop. I bought it back from Sean so it could sit in my shop till Tony S. put up the money to bring it back to life so he could race it for two years at Willow Springs.

Then I bought Lindemann Engineering. Russell L. of England bought a ‘89 TZ 250 that had LE work. Russell sent me a photo of the bike and asked for new stickers. I sent the stickers and a photo of my ‘90. This lead to Russell buying my bike.

When Russell contacted the first owner of the ‘89, Hasty Racing, they sent him old photo’s and video of it racing with the AMA. In this video Russell found our old bike with Dale racing it.

Small world. Enjoy our bike Russell!

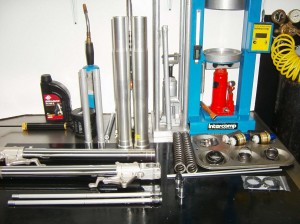

Damper Valve Assembly

This is a disassembled Compression valve. Starting from the top:

Nut to hold everything together.

Hard to see spring and cupped spring holder, this is the top of the one way valve, flip over to install.

Spacer.

One way valve washer, moves up and down on the spacer and is held closed by the spring.

Piston, oil flows through this.

4 thin washers that make up this stock “stack,” they bend to control the flow of oil through the piston.

Spacer.

Comp valve holder, slow speed oil flows through the hole in the center.

The rebound assembly looks almost the same.

The part that does the work is the washer stack. Back in the day, pistons restricted oil flow and had to be replaced but now days the pistons flow more oil than is being displaced so it’s all about the stack.

We change the stack to get the damping curve we want.

Levitation

Oscar’s Art

Caged

Notes to the new owner.

What do you do when you sell your old race bike that you did lots of neat things to? You want the new owner to know and appreciate your work but some of it’s subtle and might be missed. You put notes all over the bike before you ship.

This is a rear view, you can see one note hanging near the foot peg.